New gas pipeline custody transfer flow measurement that increases your profits

If your business involves the transportation and storage of midstream natural gas, you are constantly on the lookout for ways to improve the safety and security of your product, your processes, and your bottom line. To meet these goals, you need to adhere to the American Gas Association’s AGA-9 guidelines for custody transfer flow measurement, and you must find affordable ways to meet these AGA-9 recommendations as well as ever-increasing governmental regulations – all while minimizing costs and maintaining safety. In this quest, pipeline operators are tasked with balancing performance, safety, and ease of use with the protection of profits. All these factors must be taken into consideration while retaining firm control over lost and unaccounted flow of products as well as managing the workforce that maintains the transportation systems.

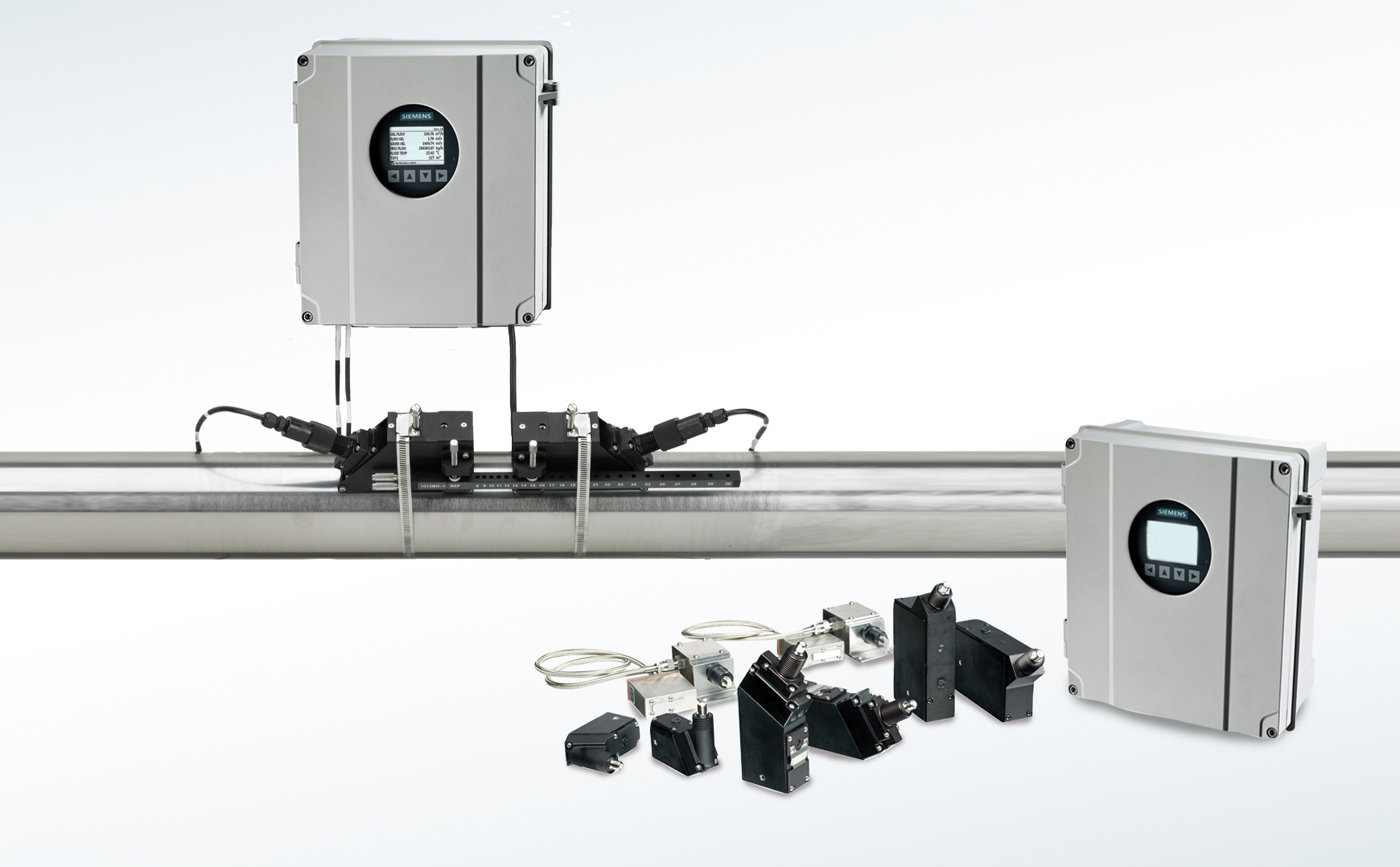

(Images provided by Siemens. Used with permission)

Midstream transportation companies are continually seeking to maximize shareholder returns by focusing on the minimization of capital and operating expenses. Pipeline engineers search for opportunities to streamline their infrastructure and processes throughout the production facilities, transmission pipelines, storage facilities, and distribution networks. Never has the need for expense reduction been more intense than in the past year, with the onset of the global pandemic and the reduced demand that has applied a downward push to the price of natural gas.

Since the introduction of ultrasonic flow meters into the gas pipeline market years ago, inline ultrasonic transmitters have remained the gold standard for accurately measuring gas in custody transfer applications and meter balancing. Both inline and clamp-on ultrasonic flow meters calculate gas flow rate by measuring the transit time of high-frequency sound pulses between two or more transducers on or in the pipeline. Extremely accurate and reliable multipath ultrasonic metering systems with two or more paths (four or more transducers) are the measurement technology of choice for gas custody transfer applications. This is due to the ongoing improvement in signal processing power of multipath instruments and their ability to provide state-of-the-art gas flow measurement. However, some of the most significant advances are being seen in clamp-on ultrasonic flow measurement. Inline meters cannot compete with the latest developments in clamp-on technology, including high-speed processing and ease of installation, operation, and service. The key advantage of clamp-on ultrasonic custody transfer flow measurement is the savings in capital and operating expenditures. Clamp-on ultrasonic meters used for custody transfer are less expensive to purchase and maintain over time.

Traditional multipath inline custody transfer sensors typically start at $80,000 per unit, a cost that rises exponentially with increasing pipe size and the number of transducers required. The price further swells if calibration, testing, and cleaning processes are factored in. Inline meters need to be shipped to calibration/testing facilities if required to be calibrated after maintenance. This testing and calibration causes the total cost of ownership to skyrocket. Additionally, the transducers used on inline ultrasonic meters are set into pockets in the pipe’s flow path, which can promote contaminate buildup that requires cleaning. The pipe must first be shut down and purged to remove and clean the individual transducers, adding further expense.

If there were a way to greatly curtail or eliminate the service for inline sensors, this savings could greatly reduce the total cost of ownership for a custody transfer flow meter. Additionally, if serviceability could be improved without the need to shut down and purge the pipeline, this, too, would lower the costs associated with a flow sensor.

These very requirements are the features that give clamp-on ultrasonic custody transfer flow meters an advantage. Externally mounted transducers ensure that installation, service, and maintenance can be performed easily, without disturbing or shutting down the pipe flow. Because the transducers are external to the pipe, there are no pockets or voids to collect contamination, resulting in less of a need for internal cleanings and costly shutdowns. As the transducers are externally mounted on a spool piece of your design, the internal surface can be conditioned, coated, or polished to further reduce the possibility of buildup. Therefore, with the need for cleaning decreased, the total cost of ownership of a clamp-on ultrasonic flow meter is significantly reduced.

By eliminating the ports in a pipe necessary to hold inline transducers, possible leak paths are also reduced, increasing the level of safety with the utilization of a clamp-on meter. If a transducer must be replaced on a clamp-on ultrasonic system, it is, again, not necessary to shut down pipe flows or evacuate the line. Transducer service and replacement can continue while the pipe is in use. If there is a need to change out a transducer on a multi-path clamp-on system, the meter can continue to measure flow with only a slight decrease in accuracy measuring using the remaining path or paths. Service time of an insertion transducer can be more than four hours; the same procedure takes mere minutes with a clamp-on ultrasonic flow meter. The minimal service and maintenance costs of a clamp-on system further contribute to the low total cost of ownership as compared to that of an inline system.

Once the clamp-on ultrasonic meter is purchased and installed on an engineered spool and then calibrated, the meter run will easily meet AGA-9 requirements for custody transfer accuracy. What is most critical for today’s midstream pipeline companies is that the clamp-on ultrasonic solution can be put into service at a much lower cost than an inline custody transfer meter run. Even after factoring in the addition of inline flow conditioners and an engineered spool piece, a typical 16-inch gas meter run can generate savings of $100,000 as compared to the price of a multipath inline custody transfer flow meter. By reducing cleaning and recalibration requirements, ensuring easier and faster service and maintenance, and improving the safety of pipelines, products, and teams in the field, the clamp-on ultrasonic custody transfer flow solution will yield increased profits for midstream gas suppliers far into the future.

This content is sponsored by Siemens. Sponsored content does not necessarily reflect the editorial views of P.I. Process Instrumentation.